Products

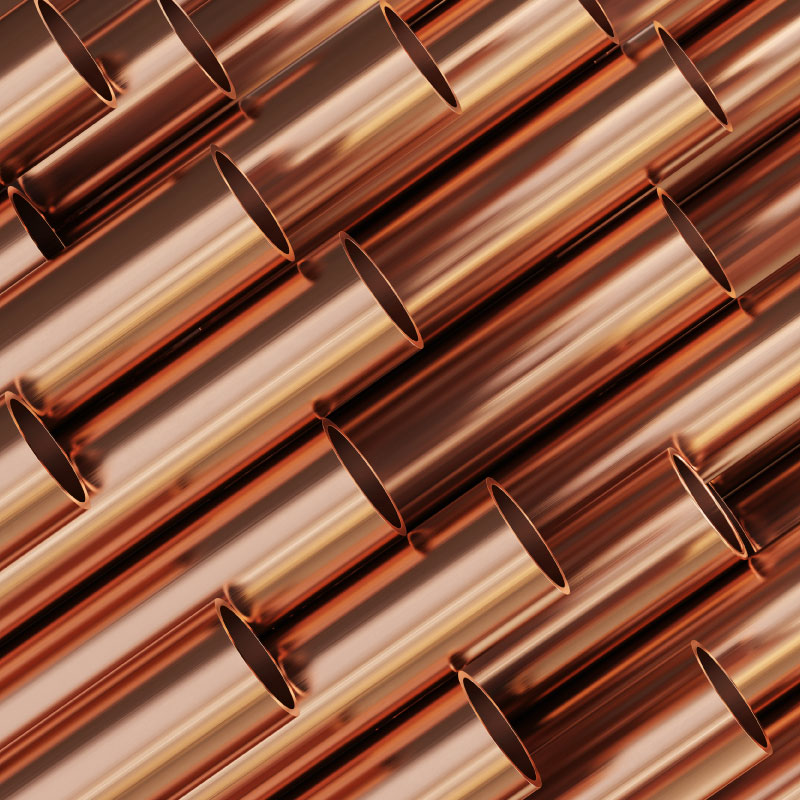

Coil, Strip, Sheet, & Plate Specifications

Coil & Strip

Alloys C10100, C10200, C11000, C12200, other alloys please inquire

- Tempers available: Soft O60, Non-Earing DDQ O68, Rolled to temper H00 through H10

- Standard Specifications: ASTM B152, ASTM B370 for Building and Construction

- Gauge Tolerance: ASTM B248 ½ Commercial is typical

- Gauge range: .0022″ – .500″

- Width range: 1″ – 38.5″

Sheet

Alloys C10100, C10200, C11000, C12200, other alloys please inquire

- Tempers available: Soft O60, Non-Earing DDQ O68, Rolled to temper H00 through H02

- Standard Specifications: ASTM B152, ASTM B370 for Building and Construction

- Gauge Tolerance: ASTM B248 ½ Commercial is typical

- Gauge range: .016″ – .250″

- Width range: 15″ – 38″

- Length range: 36”-144”

Plate

Alloys C10100, C10200, C11000, C12200, other alloys please inquire

- Tempers available: Light Cold Rolled to temper H00 through H01

- Standard Specifications: ASTM B152

- Tolerances: ASTM B248 Commercial is typical

- Gauge range: .375”-1.25”

- Width range: 15″ – 38″

- Length range: 72”-144.5”

Bar Specifications

Rome Cold Rolled Bar

Alloy C11000

ASTM B187; ASTM B152

- H02 Half Hard Temper

- Finished Edges (Square, Full Round, Radius Corner): .125” – .500” gauge, 2” – 8.250” width

- Sawed Edges: Over .500” – 1.00” gauge, 2” – 12” width

- Bare Bar Lengths: 72” to 240” (Standard 144”)

- Coil Sizes: 16-20” ID (2” range), full or half PIW, .125” – .250” gauge, 1” – 6” width, available as bare only

- Silver Flash Lengths: 72” to 144”

- Silver Flash Thickness: Nominal .000005” Checked by Kocour Coulimetry

Mebane Continuous Rotary Extruded & Drawn Bar

Alloy C10200

*Can be certified to meet C11000 upon request

ASTM B187

- H02 Half Hard Temper

- Finished Edges (Square, Full Round): .050” – .5625” gauge, .500” – 6.499” width

- Bare Bar Lengths: 72” to 240” (Standard 144”)

Coils Now Available

Silver Flash Now Available

Please note any of the range limits are what is typically used and are open to discussion. We can work with you to provide exactly what you need.

General characteristics for our finished products:

99.9% min Cu for 110

99.9% min Cu for 122, 0.015 – .040% P

99.99% for C101, 99.95% for C102

97.2% min %IACS (Conductivity) for 110

0.15775% max Res.

Tempers to include 068 – H06 to start

Electrical Capabilities

For electrical end use, bar product rolled formed to produce square edge, rounded corners, and full round edge offered as bare or silver flashed. Silver or tin electroplated available through third-party platers.

Most material is produced to conform to industry standard accepted specifications found in ASTM and cite B152, B370, and B187.

We offer lab tests that can be requested by contacting us.